Panther Partner Spotlight: Ionel Popa – Exploring Soft Materials for Medicine, Industry & Beyond

At the crossroads of physics, biology, and chemistry, Ionel Popa’s UWM lab explores the mechanics of soft biomaterials—proteins, tissues, and polymers so delicate they behave almost like liquids. By building custom tools and experimental approaches, his team is uncovering how these materials function and applying that knowledge to advance drug screening, diagnostics, and bio-inspired products. With expertise spanning biomaterials and instrumentation design, the lab is eager to collaborate with partners in biotech, pharma, food science, and advanced materials—transforming fundamental science into practical solutions.

Tell us about your main areas of expertise.

My work sits at the crossroads of physics, biology, and chemistry, where I explore how proteins behave under mechanical stress. In simpler terms, I study how tiny biological building blocks—proteins—stretch, interact, and move, and how those movements affect things like muscle contraction, bacterial infection, and even how cancer spreads.

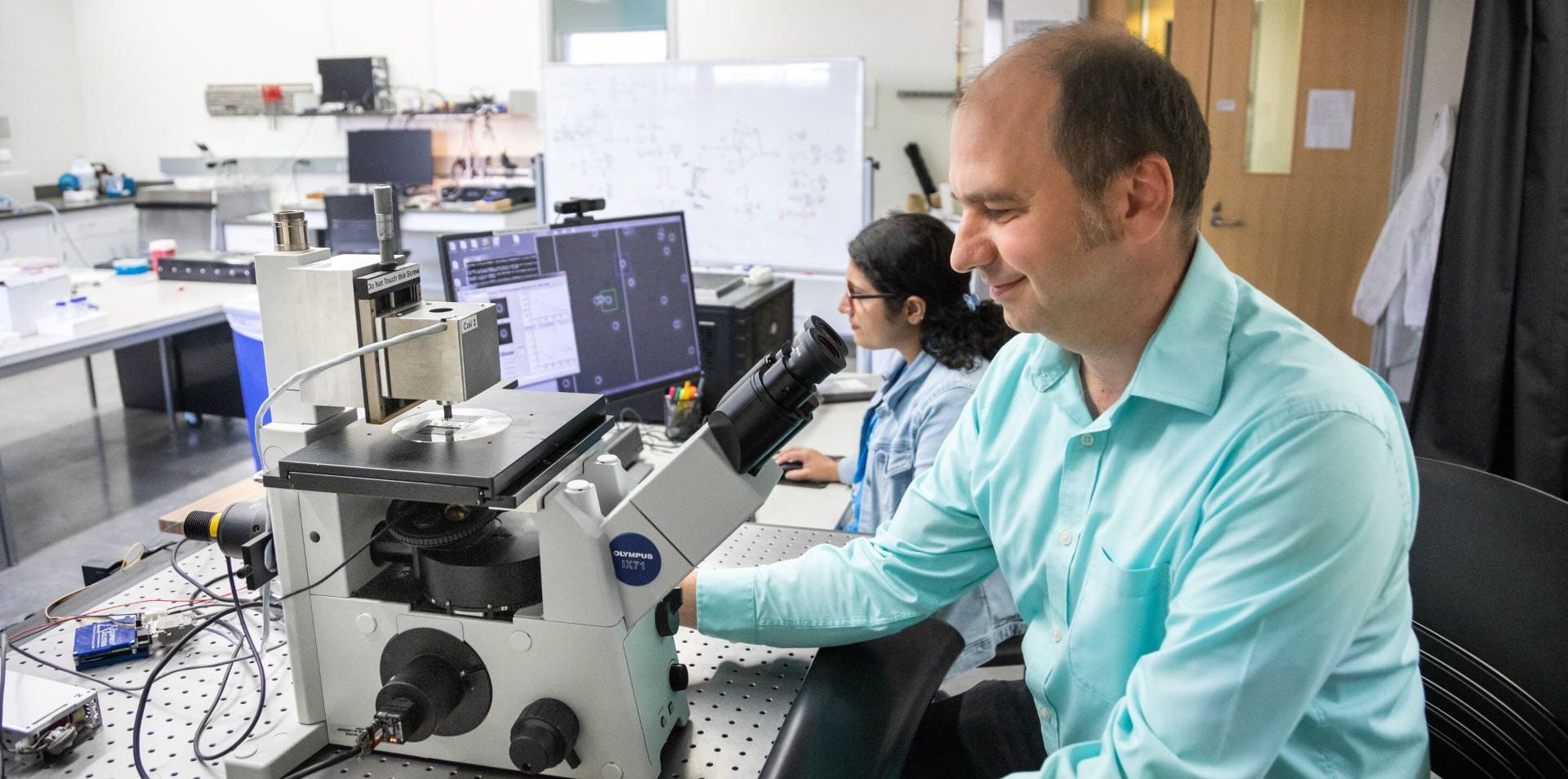

To do this, my lab builds custom tools and uses advanced microscopy to observe proteins in action. We’re not just interested in the science for its own sake—we aim to turn our discoveries into practical solutions. For example, we’re developing new ways to screen for antibiotics that block bacteria from attaching to human cells. We also study how mutations in muscle proteins can lead to disease, and how cells communicate with each other, which has implications for cancer research.

Ultimately, our goal is to create new biomaterials and technologies that can be used in medicine and industry.

What are some ways you can help companies or outside collaborators?

My lab specializes in designing custom experiments and building specialized tools to study soft biomaterials—materials so delicate they can behave almost like liquids. These include biological tissues, protein-based materials, and polymers that are too soft for traditional testing equipment.

We’ve developed new instrumentation for fluorescence microscopy and mechanical testing, which allows us to study how molecules interact, how cells behave, and how materials respond to stress. Through a shared facility I co-lead, we can help companies automate drug screening, analyze molecular interactions, and characterize the mechanical properties of soft materials.

We’re also working on a startup to offer screening services to pharmaceutical companies. Using our custom-built instruments, we can help identify promising compounds from drug libraries—whether they’re provided by the company or sourced externally. Our tools are especially useful for targeting specific receptors or disease models.

In short, we offer expertise in soft matter characterization, custom instrumentation, and experimental design—especially for companies in biotech, pharma, and materials science.

Have you worked with companies before? If so, in what ways?

Before coming to Milwaukee, I collaborated with industry partners on a few projects. One example from my PhD work involved a Swiss perfume company that wanted to embed fragrance into tiny beads within laundry detergent. The goal was for the perfume to release gradually as the fabric moved—essentially a mechanically triggered release system. My role was to help measure how the fragrance was released, which tied into my expertise in soft materials and mechanical interactions.

Here in Wisconsin, I’m eager to build similar partnerships. In addition to the screening services startup I mentioned earlier, I’m exploring opportunities to advance our antibody binding column technology with the right industry partner. This technology improves on existing antibody purification products, by having better yield and faster pass-through times.

I also see potential for collaboration in industries like food and beverage, where understanding the mechanical properties of formulations—like cheese textures—can be valuable. Adhesives and other soft matter applications are also a natural fit for our expertise.

What sectors or industries are you most interested in working with?

My lab is especially well-suited for collaborations in biotechnology and advanced materials. We focus on developing bio-inspired products and materials with unique mechanical properties—like super-elastic materials that can stretch significantly without breaking.

We’re also very interested in working with medical device companies and diagnostics startups. Our expertise in protein mechanics and soft biomaterials makes us a strong fit for projects involving biological sensing, tissue engineering, or molecular diagnostics.

Whether it’s creating new biomaterials, building custom instrumentation, or helping companies understand how their products behave at the molecular level, we’re excited to work with partners across these sectors.

Tell us one fun fact about you, personally or professionally.

Once, I assembled an IKEA piece of furniture incorrectly—but I kept it that way because it actually worked better than the original design. It’s a funny story, but it also reflects something important about how I approach science: seeing things differently. In research, everyone might be looking at the same data, but success often comes from noticing what others don’t. That mindset—questioning assumptions and finding unexpected solutions—is something I bring to both my lab and collaborations.