OTT1582

Applications

Electric Vehicles (EV), smart electronics, low-cost batteries for consumer electronics, sensors

Target Problems

An important goal of the battery industry is extending battery lifetime. Conventional LIBs are primarily based on graphite negative electrodes (NE) and lithium metal oxide (LMO) positive electrodes (PE) and their energy densities are typically 150 ~ 200 Wh kg-1, which struggle to fulfill the increasing demand.

Key Features

- Reduces Initial Capacity Loss – h compensate for the initial capacity loss during SEI formation

- Easier to Manufacture – can be prepared in ambient conditions without a dry room

- Retrofit – can be easily fit into existing manufacturing process without substantial capital expenditure

- Strong Performance – increase in capacity per unit volume to enable longer driving distance and usage time

- Reduces SEI – pre-lithiation compensates for active loss through SEI

- Improves – available energy densities of Li-Ion Batteries

Technology

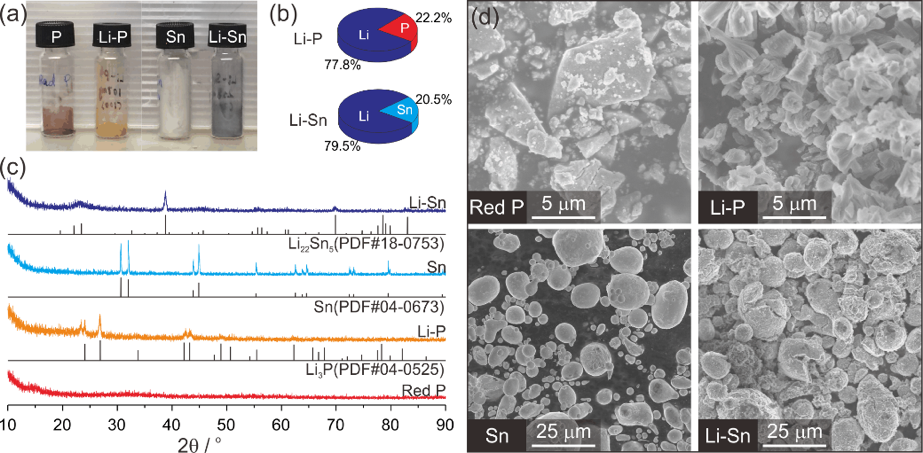

Inventors at University of Wisconsin, Milwaukee (UWM) have created a family of chemical additives to mitigate lithium-ion losses during solid electrolyte interphase (SEI) formation in Lithium-Ion Batteries (LIB) to meet the ever-growing performance requirements. These chemical additives and methods make extra lithium ions available during charge discharge cycles thereby slowing capacity fade. This new additive addition process easily integrates with existing manufacturing processes and can also be used with sodium ion batteries.

Intellectual Property

Pending PCT application

Inventor