OTT1294

Technology

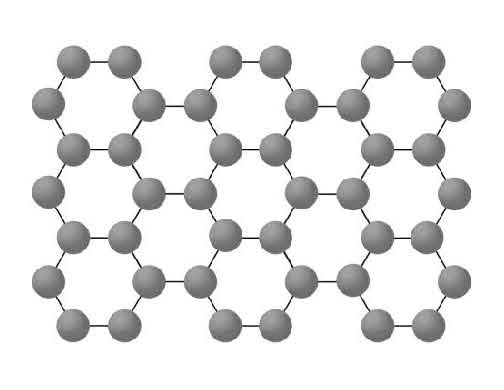

This technology entails a new material, graphene monoxide (GMO), comprised of a unique one-toone carbon-oxygen structure with crystal ordering for both oxygen and carbon atoms and having a theoretical band gap of ~ 0.9 eV. The band gap of GMO is also adjustable with the capability to span both the direct and indirect semiconductor range. Graphene Monoxide is one of the first structures in the carbon family that acts as a semiconductor-a critical component to electronics.

The precursor material is graphene oxide, an insulator, and after the manufacturing process, it is GMO which acts as a semiconductor. Initial studies have shown the method can be adjusted to control the location of GMO in addition to the graphene/GMO content. The technology is at at the early development stage with small scale feasibility application testing in the planning stage.

Features/Benefits

- Real-time Band Gap Tuning – Applying a strain to GMO theoretically shifts the band gap

- Mass Production – Thermal reduction in vacuum method increases potential for mass production of GMO

- Oxygen Tuning – Water vapor can be used to tune the oxygen content during the production of GMO on Graphene Oxide

- Future Applications – promising applications in nanoelectronic and electrochemical devices

Intellectual Property

US2013-0344390 Issued 2015.

The inventors are currently looking for industry partners to test the materials in specific applications.

Markets

According to a report conducted by semiconductor industry association, the world semiconductor market reached over $27 billion as of April 2016 and is expected to grow at a moderate pace of 2.0% growth globally by 2017. The commercialization of graphene monoxide as a semiconductor would redefine the limits on what can be achieved with electronics and change the semiconductor market.

Graphene Monoxide is expected to be a suitable anode for battery technologies and electrode for ultracapacitors, in addition to semiconducting applications. The lithium ion battery market is expected to grow over 700% from 2011 through 2017, from a $2 billion to a projected $14.6 billion market.

According to a study by Pike Research worldwide sales of ultracapacitors is anticipated to reach $284 million by 2016.

Inventor (s)

Junhong Chen, PhD, Marija Gajdardziska-Josifovska, PhD, Carol Hischmugl, PhD, and Eric Mattson

Dr. Junhong Chen is a professor in the Department of Mechanical Engineering at UW-Milwaukee. His research focuses on nanomaterial innovations, specfiicaclly in the areas of carbon nanotubes, graphene, and hybrid nanomaterials. The materials developed in Dr. Chen’s lab are characterized and have been applied to applications including nanostrucuture-based gas sensors, biosenors, lithium-ion bateries, solar cells, liquid sensors, and water treatment. Dr. Chen is the director of both the NSF I/UCRC on Water Equipment and Policy and the Laboratory of Nanotechnology for Sustainable Energy and Environment.

Dr. Marija Gajdardziska-Josifovska is a professor in the Department of Physics at UW-Milwaukee. She is also the Associated Dean of Natural and Biomedical Sciences and Engineering within the Graduate School at UW-Miwlaukee. Her research uses atomic resolution transmission electron microscopy, differaction, and spectroscopy methods to understand how the combination of iconicity and limited dimensionality leads to new physical properties and applications.

Dr. Carol Hirschmugl is a professor in the Department of Physics at UW-Milwaukee. Her area of expertise is the study of surface adsorbates on epitaxial and bulk oxide systems, focusing on environmentally and technologically relevnt problems. Dr. Hirschmugl is the director of the Laboratory for Dynamics and Structure at Surfaces.

Publications

Mattson EC, Pu H, Cui S, Schofield MA, Rhim S, Lu G, Nasse MJ, Ruoff RS, Weinert M, GajdardziskaJosifovska M, Chen J, Hirschmugl CJ. 2011. Evidence of nanocrystalline semiconducting graphene monoxide during thermal reduction of graphene oxide in vacuum. ACS Nano 5(12): 9710-7.